Description

Key Features:

Quick and Easy Installation:

Save time with fast installation, minimizing downtime, and keeping systems running smoothly.

Thermo Paint Coating:

Provides enhanced protection and a smooth, durable surface, increasing the longevity of the cable.

Mechanical Stress Protection:

Safeguards cables from external damage, preventing wear and tear for extended service life.

Customizable Length:

The sleeve and channel can be easily cut to suit shorter applications, offering flexibility in repair jobs.

Moisture-Resistant Seal:

The hot melt adhesive creates a strong, moisture-resistant bond, preventing water ingress and enhancing protection.

Versatile Fit:

Accommodates a wide range of cable sizes, making it a versatile solution for various applications.

Applications:

Cable Insulation:

Ideal for insulating cables, ensuring protection and reliable performance in harsh conditions.

Cable Repair:

Perfect for repairing damaged cables, providing quick fixes and additional protection in industrial systems and power distribution networks.

Shelf Life & Storage:

The RCS-RSL Heat Shrink Cable Repair Sleeve has a shelf life of over 5 years when stored in a humidity-controlled environment (temperature range -10°C to 40°C, relative humidity <75%).

Ordering Information:

- Standard Colors: Black (custom colors available upon request)

Technical performances:

| Properties | Test Condition and Method | Requirement |

| Bursting Strength | Test Temp: 23 ±5℃ | 15MPa min. |

| Thermal Ageing | 168 hrs at 150℃±2℃ | 13.7MPa min |

| Bursting strength | After free shrinkable | 14MPa min |

| Dielectric strength | Electrode Surface

Dia: 6mm Wight: 50±2gms Voltage steps: 2kV/20sec |

Min 12kV/mm |

| Split Resistance | Temp: 200±2℃

Test time 23±3℃ |

No split

Propagation |

| Carbon Content

UV Res of Out/layer |

Heating rate: 20℃/min

Gas flow rate: 300cc/min |

Min 2.6±0.25% |

| Cold Crack Resistance | Test temp ≤ -40℃ | No cracking |

| Resistance to aggressive

media Bursting Strength |

Test media: Fuel oil, petroleum

jelly Test temp: 70±2℃ |

Min 13.7MPa |

| Environmental

Stress cracking |

10% Igepal Co 630

solution immersion Time 30 days Test Temp: 50±3℃ |

No cracking |

| Temp. indicating

paint conversion |

Completely conversion | Completely conversion |

| Properties of adhesive | ||

| Adhesive Softening Point | ASTM E28 | 90±10℃ |

| Peel Strength | -PE at 23±2℃

-Pb at 23±2℃ |

Min 70N |

| Shear Strength | At 23±2℃

Copper Mirror test Test time: 16hrs Test temp: 60±℃ |

Min 100N |

| Corrosive Effect | ASTM D 1693 | No effect |

Selection table:

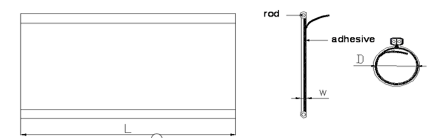

| Size (mm) | As supplied(mm) | After recovered(mm) | Standard Length | ||

| D*(mm) | W*(Min.) | d*(Max.) | w*(Min.) | L(mm) | |

RCS-RSL 36/10 |

38 | 0.7 | 10 | 3.2 | 500, 750, 1000, 1500 |

RCS-RSL 55/13 |

57 | 0.7 | 13 | 3.2 | 500, 750, 1000, 1500 |

RCS-RSL 85/20 |

85 | 0.7 | 20 | 3.2 | 500, 750, 1000, 1500 |

RCS-RSL 108/27 |

110 | 0.7 | 27 | 3.2 | 500, 750, 1000, 1500 |

RCS-RSL 136/30 |

138 | 0.7 | 30 | 3.2 | 500, 750, 1000, 1500 |

RCS-RSL 180/50 |

183 | 0.7 | 50 | 3.2 | 500, 750, 1000, 1500 |

*NOTE:

1. D*= Diameter as supplied

2. d* = Diameter after recovered

3. W*= Thickness of sleeve as supplied

4. w*= Thickness of sleeve after fully recovered