Description

Key Features:

Triple-Layer Construction:

The RCS-TRT Tubing features a unique triple-layer design, combining semi-conductive, insulating, and elastomeric layers. This provides comprehensive protection against electrical faults, ensuring optimal performance and durability in demanding conditions.

Co-Extruded Design:

Manufactured using a co-extrusion process, the tubing ensures consistent quality and precision across all layers, delivering reliable performance and longevity in medium voltage cable systems.

Heavy Insulation Layer:

The extra heavy insulation layer offers enhanced electrical protection, effectively isolating cables and preventing electrical faults. This robust construction also provides mechanical strength, ensuring long-term reliability.

Shrink Ratio 3:1:

With a 3:1 shrink ratio, the RCS-TRT Tubing is compatible with a wide range of cable sizes, reducing inventory complexity and simplifying installation processes.

High-Temperature Recovery:

The tubing fully recovers at a minimum temperature of 130℃, ensuring a tight, secure fit even in extreme temperature conditions. This guarantees both mechanical durability and electrical reliability.

Voltage Rating:

Suitable for medium voltage applications up to 42kV, the RCS-TRT Tubing meets stringent industry standards, providing reliable insulation and protection for critical cable systems.

Applications:

Medium Voltage Cable Insulation:

Ideal for use in medium voltage systems, the RCS-TRT Tubing provides electrical insulation, jointing, and termination for cables operating up to 42kV.

Harsh Environments:

Designed for environments that demand advanced electrical insulation and robust mechanical protection, this tubing ensures reliable performance even in challenging conditions.

Cable Protection:

Suitable for cable insulation and protection in medium voltage applications, where both electrical and mechanical durability are critical for safe and efficient system operation.

Why Choose RCS-TRT Heat Shrink Tubing?

- Comprehensive Protection: The triple-layer construction provides superior electrical insulation and mechanical protection for medium voltage cable systems.

- Advanced Co-Extrusion Manufacturing: Ensures consistent quality and precision, delivering reliable performance over the lifetime of the installation.

- Versatile Installation: The 3:1 shrink ratio accommodates a wide range of cable sizes, simplifying installation and reducing the need for multiple tubing sizes.

- High Temperature Resilience: Fully recovers at 130℃, ensuring a secure and durable fit, even in extreme temperature conditions.

Typical technical performances:

Test Items |

Test Method |

Test Requirements |

Insulation layer |

||

| Tensile strength | ASTM D 2671 | 10MPa min. |

| Ultimate elongation | ASTM D 2671 | 200% min. |

| Volume resistivity | IEC 93 | 1014Ω.cm max. |

| Water absorption | ISO 62 | 0.5% max. |

Elastomer layer |

||

| Tensile strength | ASTM D 2671 | 5MPa min. |

| Ultimate elongation | ASTM D 2671 | 500% min. |

| Volume resistivity | IEC 93 | 1014Ω.cm min. |

Semi-conductive layer |

||

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 200% min. |

| Volume resistivity | ASTM D 257 | 104Ω.cm max. |

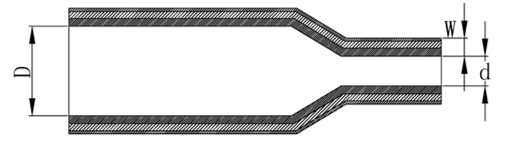

Dimensions:

Size (mm) |

As supplied (mm) |

After recovering (mm) |

Standard Length (m) |

|

D*(Min.) |

d*(Max.) |

w(Min.) |

||

RCS-TRT 36/12 |

36 | 12 | 7.3 | 1.0-1.22 |

RCS-TRT 46/15 |

46 | 15 | 7.3 | 1.0-1.22 |

RCS-TRT 50/18 |

50 | 18 | 7.3 | 1.0-1.22 |

RCS-TRT 56/21 |

56 | 21 | 7.3 | 1.0-1.22 |

RCS-TRT 62/25 |

62 | 25 | 7.3 | 1.0-1.22 |

RCS-TRT 70/30 |

70 | 30 | 7.3 | 1.0-1.22 |

RCS-TRT 80/36 |

80 | 36 | 7.3 | 1.0-1.22 |

RCS-TRT 95/40 |

95 | 40 | 7.3 | 1.0-1.22 |

RCS-TRT 120/50 |

120 | 50 | 7.3 | 1.0-1.22 |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered