Description

Key Features:

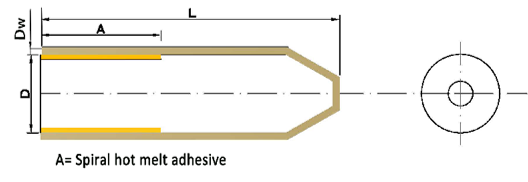

Spiral Adhesive Coating (Optional):

Offers a moisture-resistant seal for added protection, ideal for environments requiring extra sealing strength.

UV Resistant:

Built to endure prolonged outdoor exposure, maintaining performance and integrity over time.

Available in Insulating and Conductive Types:

Choose the right solution based on your application requirements—whether for insulating or conductive needs.

Shrink Ratio 3:1

Accommodates a wide range of cable sizes, reducing inventory requirements and improving installation flexibility.

High-Temperature Performance:

Fully recovers at a minimum temperature of 120℃, ensuring a tight and secure fit around the cable termination.

Applications:

Cable Termination Insulation:

Ideal for providing insulation at cable terminations in both medium and high-voltage electrical systems.

Protection and Sealing:

Offers enhanced sealing and protection for cables in industrial and power distribution applications where insulation and secure terminations are essential.

Shelf Life & Storage:

The RCS-SEC Heat Shrink Insulating Endcap has a shelf life of over 5 years when stored in a humidity-controlled environment (temperature range -10°C to 40°C, relative humidity <75%).

Ordering Information:

Standard Colors: Black (custom colors available upon request)

Typical technical performances:

| Test Items | Test Method | Test Requirements |

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 200% min. |

| Volume resistivity | IEC 93 | 1014Ω.cm min. |

| Dielectric strength | IEC 60243 | 12kV/mm(1.0mm) min. |

| Water absorption | ISO 62 | 0.5% max. |

| Heat shock at 225℃/4hrs | ASTM D 2671 | No cracking, dropping |

| Density | ASTM D 792 | 1.0~1.1g/cm3 |

Dimensions:

| Size | As supplied(mm) | After recovered(mm) | ||||

| (mm) | L*(±10%) | D*(Min.) | A*(±10%) | d*(±10%) | l*(±10%) | Dw(±10%) |

Cable end cap-RCS-SEC, standard length |

||||||

RCS-SEC 105 12/4 |

38 | 12 | 15 | 4 | 40 | 2.6 |

RCS-SEC 110 14/5 |

45 | 14 | 18 | 5 | 42 | 2.2 |

RCS-SEC 115 20/6 |

65 | 20 | 25 | 6 | 55 | 2.5 |

RCS-SEC 120 25/8.5 |

75 | 25 | 30 | 8.5 | 65 | 2.5 |

RCS-SEC 130 35/16 |

92 | 35 | 35 | 16 | 83 | 3.3 |

RCS-SEC 135 40/15 |

95 | 40 | 40 | 15 | 75 | 3.3 |

RCS-SEC 140 55/26 |

114 | 55 | 50 | 26 | 105 | 3.5 |

RCS-SEC 150 75/36 |

132 | 75 | 55 | 36 | 115 | 4.2 |

RCS-SEC 160 100/52 |

153 | 100 | 70 | 52 | 130 | 5.0 |

RCS-SEC 170 120/60 |

155 | 120 | 70 | 60 | 150 | 5.0 |

RCS-SEC 180 145/60 |

160 | 145 | 70 | 60 | 150 | 5.0 |

RCS-SEC 190 160/82 |

160 | 160 | 70 | 82 | 133 | 4.5 |

RCS-SEC 200 200/90 |

170 | 200 | 70 | 90 | 145 | 4.5 |

L* = Length of end cap as supplied

D* = Inner diameter as supplied

A* = Length of adhesive after fully recovered

d* = Inner diameter after fully recovered

l* = Length of end cap after fully recovered