Description

Key Features:

Dual-Wall Co-Extruded Construction:

The RCS-RTM tubing features a co-extruded design with an inner hot melt adhesive lining, providing excellent moisture sealing and protection against contaminants.

UV Resistant:

Designed to withstand extended outdoor exposure, this tubing maintains its integrity and performance under harsh environmental conditions.

Flame Retardant:

This tubing is engineered to meet specific industry standards for controlled flammability, ensuring safety in high-voltage applications.

Semi-Rigid Design:

Combining flexibility with robust mechanical performance, the semi-rigid design ensures easy installation without compromising protection.

Shrink Ratio 3:1:

The 3:1 shrink ratio accommodates a wide range of cable sizes, simplifying inventory management and reducing installation complexity.

High-Temperature Recovery:

This tubing fully recovers at a minimum of 120℃, ensuring a tight, secure fit for reliable insulation and sealing.

Applications:

Medium-Voltage Cable Insulation and Protection:

Ideal for insulating and sealing medium-voltage cables in demanding environments, the RCS-RTM tubing offers mechanical protection and long-term durability.

UV and Environmental Resistance:

Perfect for use in outdoor applications, this tubing offers reliable moisture resistance and UV protection in harsh environments.

Why Choose RCS-RTM Heat Shrink Tubing?

The RCS-RTM Co-Extruded Medium Wall Tubing provides exceptional protection for medium-voltage cables. The dual-wall construction, combined with the hot melt adhesive lining, ensures reliable moisture sealing and contaminant protection, while the UV resistant and flame retardant properties make it ideal for harsh outdoor and industrial environments.

Shelf Life & Storage:

The RCS-RTM Heat Shrink Tubing has an extended shelf life of 5+ years when stored in a humidity-controlled environment (temperature range -10°C to 40°C, relative humidity <75%).

Ordering Information:

- Standard Color: Black (other colors available upon request)

Typical technical performances:

Test Items |

Test Method |

Test Requirements |

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 350% min. |

| Tensile strength after

Aging at 150℃ for 168hrs |

ASTM D 2671 | 12MPa min. |

| Ultimate elongation after

Aging at 150℃for 168hrs |

ASTM D 2671 | 300% min. |

| Density | ASTM D 792 | 1.0~1.1g/cm3 |

| Dielectric strength | ASTM D 60243 | 12kV/mm(2mm) min. |

| Volume resistivity | ASTM D 2671 | 1012Ω.cm min. |

| Low-temperature flexibility

-40℃/4hrs |

ASTM D 2671 | No cracking of the outer jacket |

| Properties of hot melt adhesive | ||

| Softening point | ASTM E28 | 105+/-5℃ |

| Peel strength(PE) | ASTM D 2671 | 4N/cm min. |

| Water absorption | ISO 62 | 0.2% max. |

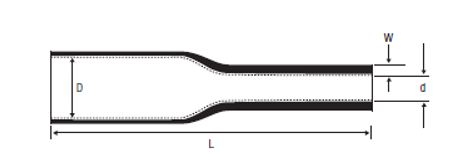

Dimensions:

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length(m) |

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length(m) |

||

D*(Min.) |

d*(Max.) |

w(Min.) |

D*(Min.) |

d*(Max.) |

w(Min.) |

||||

RCS-RTM 8/2 |

8 | 2 | 1.8 | 1.0-1.5 | 45/12 | 45 | 12 | 2.4 | 1.0-1.5 |

RCS-RTM 12/3 |

12 | 3 | 1.9 | 1.0-1.5 | 55/16 | 55 | 16 | 2.4 | 1.0-1.5 |

RCS-RTM 16/5 |

16 | 5 | 1.9 | 1.0-1.5 | 65/19 | 65 | 19 | 2.6 | 1.0-1.5 |

RCS-RTM 19/5 |

19 | 5 | 1.9 | 1.0-1.5 | 75/22 | 75 | 22 | 2.8 | 1.0-1.5 |

RCS-RTM 22/6 |

22 | 6 | 2.1 | 1.0-1.5 | 95/25 | 95 | 25 | 3.1 | 1.0-1.5 |

RCS-RTM 28/6 |

28 | 6 | 2.6 | 1.0-1.5 | 115/34 | 115 | 34 | 3.5 | 1.0-1.5 |

RCS-RTM 33/8 |

33 | 8 | 2.4 | 1.0-1.5 | 140/42 | 140 | 42 | 3.4 | 1.0-1.5 |

RCS-RTM 40/12 |

40 | 12 | 2.4 | 1.0-1.5 | 160/50 | 160 | 50 | 3.4 | 1.0-1.5 |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered