Description

Key Features:

Dual-Wall Co-Extrusion with Hot Melt Adhesive:

The robust dual-wall design combines a strong outer layer with an inner hot melt adhesive lining for enhanced moisture sealing, ensuring long-lasting protection from contaminants.

Shrink Ratio 6:1:

This tubing offers an impressive 6:1 shrink ratio, allowing it to fit a wide variety of cable sizes and reducing the need for multiple stock items, simplifying inventory management and installation.

UV Resistant:

Engineered to withstand prolonged exposure to UV light, making it highly suitable for outdoor and weather-exposed applications without deterioration.

Flame Retardant:

Meets specific standards for controlled flammability, ensuring that it performs safely in industrial environments where fire resistance is a critical factor.

Semi-Rigid Design:

The semi-rigid structure balances flexibility and mechanical durability, making it versatile for use in both demanding and flexible applications.

Custom Lengths Available:

Supplied in pre-cut lengths up to 1.5 meters, providing convenience for quick and easy application in various installations.

High-Temperature Recovery:

Recovers fully at a minimum temperature of 120℃, providing a tight, reliable fit for optimal insulation and mechanical protection.

Applications:

Medium and High-Voltage Cable Insulation and Sealing:

Ideal for protecting and insulating cables in demanding applications that require high durability, resistance to environmental factors, and superior sealing capabilities.

Harsh Environmental Conditions:

Perfect for applications in industries such as power generation, construction, and telecommunications, where cables are exposed to moisture, contaminants, UV rays, and other challenging conditions.

Why Choose RCS-RA6X Heat Shrink Tubing?

The RCS-RA6X Heavy Wall Tubing offers a high shrink ratio and dual-wall protection, ensuring superior sealing, mechanical strength, and long-lasting performance in medium and high-voltage cable applications. Designed to meet the rigorous demands of industrial environments, it provides excellent protection against moisture, contaminants, UV exposure, and mechanical stress. Its semi-rigid design and flame retardancy make it the ideal choice for a wide variety of installations, including outdoor and weather-exposed applications.

Typical technical performances:

Test Items |

Test Method |

Test Requirements |

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 350% min. |

| Tensile strength after

Aging at 150℃ for 168hrs |

ASTM D 2671 | 12MPa min. |

| Ultimate elongation after

Aging at 150℃for 168hrs |

ASTM D 2671 | 300% min. |

| Density | ASTM D 792 | 1.0~1.1 g/cm3 |

| Dielectric strength | ASTM D 60243 | 12kV/mm(2mm) min. |

| Volume resistivity | ASTM D 2671 | 1012Ω.cm min. |

| Low-temperature flexibility

-40℃/ 4hrs |

ASTM D 2671 | No cracking of the outer jacket |

| Properties of hot melt adhesive | ||

| Softening point | ASTM E28 | 85+/-5℃ |

| Peel strength(PE) | ASTM D 2671 | 4N/cm min. |

| Water absorption | ISO 62 | 0.2% max. |

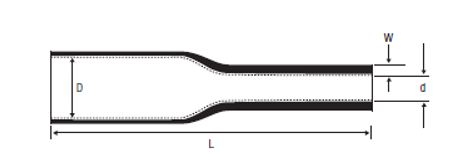

Dimensions:

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length(m) |

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length(m ) |

||

D*(Min.) |

d*(Max.) |

w(Min.) |

D*(Min.) |

d*(Max.) |

w(Min.) |

||||

RCS-RA6X 19/3.2 |

19.0 | 3.2 | 3.2 | 1.0-1.22 | 69.8/11.7 | 69.8 | 11.7 | 4.7 | 1.0-1.22 |

RCS-RA6X 33/5.5 |

33.0 | 5.5 | 3.4 | 1.0-1.22 | 88.9/17.1 | 88.9 | 17.1 | 4.7 | 1.0-1.22 |

RCS-RA6X 44.4/7.4 |

44.4 | 7.4 | 3.6 | 1.0-1.22 | 119.4/22.9 | 119.4 | 22.9 | 4.7 | 1.0-1.22 |

RCS-RA6X 50.8/8.3 |

50.8 | 8.3 | 4.7 | 1.0-1.22 | 235/40 | 235.0 | 40.0 | 4.7 | 1.0 |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered