Description

Key Features:

Dual-Wall Design (RCS-RA2):

The dual-wall design features an inner layer of hot melt adhesive, providing a secure, moisture-resistant seal that enhances the protection of cables.

Customizable Lengths:

Supplied in cut pieces up to 1.5 meters, this tubing allows for flexible and efficient usage in a variety of installations.

UV Resistant:

The UV-resistant material ensures long-lasting durability, even in outdoor environments with prolonged exposure to sunlight.

Semi-Rigid Construction:

Combining flexibility with robust mechanical performance, the semi-rigid construction ensures easy installation and reliable protection.

Flame Retardant:

The flammable properties meet specific safety requirements for applications that require controlled flammability.

Shrink Ratio 3:1:

The 3:1 shrink ratio accommodates a wide range of cable sizes, reducing inventory needs and simplifying installation.

High-Temperature Recovery:

The tubing fully recovers at a minimum temperature of 120℃, ensuring a tight and secure fit, even in high-temperature environments.

Applications:

Medium-Voltage Cable Insulation and Repair:

The RCS-R2/RCS-RA2 tubing is ideal for insulating and repairing medium-voltage cables, providing both mechanical protection and electrical insulation.

UV and Environmental Protection:

Perfect for outdoor applications, offering UV resistance and reliable protection against moisture and environmental stresses.

Why Choose RCS-R2/RCS-RA2 Medium Wall Tubing?

The RCS-R2/RCS-RA2 provides excellent protection for medium-voltage cables, with the flexibility to meet various application needs. The dual-wall design, featuring an inner hot melt adhesive lining, ensures superior moisture resistance and sealing, while the UV-resistant properties ensure durability in outdoor environments.

Shelf Life & Storage:

The RCS-R2/RCS-RA2 Heat Shrink Tubing has a shelf life of over 5 years when stored in a humidity-controlled environment (temperature range -10°C to 40°C, relative humidity <75%).

Ordering Information:

- Standard Color: Black (other colors available upon request)

Typical technical performances:

| Test Items | Test Method | Test Requirements |

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 350% min. |

| Tensile strength after

Aging at 150℃ for 168hrs |

ASTM D 2671 | 12MPa min. |

| Ultimate elongation after

Aging at 150℃ for 168hrs |

ASTM D 2671 | 300% min. |

| Density | ASTM D 792 | 1.0~1.1g/cm3 |

| Dielectric strength | ASTM D 60243 | 12kV/mm(2mm) min. |

| Volume resistivity | ASTM D 2671 | 1012Ω.cm min. |

| Low-temperature flexibility -40℃/4hrs | ASTM D 2671 | No cracking of the outer jacket |

| Properties of hot melt adhesive | ||

| Softening point | ASTM E28 | 85+/-5℃ |

| Peel strength(PE) | ASTM D 2671 | 4N/cm min. |

| Water absorption | ISO 62 | 0.2% max. |

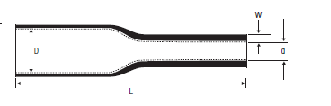

Dimensions:

RCS-RA2 Medium wall tubing with hot melting adhesive |

|||||||||

| Size

(mm) |

As supplied

(mm) |

After recovered

(mm) |

Standard length

(m) |

Size

(mm) |

As supplied

(mm) |

After recovered

(mm) |

Standard length

(m) |

||

| D*(Min.) | d*(Max.) | w*(Min.) | D*(Min.) | d*(Max.) | w*(Min.) | ||||

| 8/2 | 8 | 2 | 1.8 | 1.0-1.5 | 95/25 | 95 | 25 | 3.6 | 1.0-1.5 |

| 12/3 | 12 | 3 | 1.8 | 1.0-1.5 | 115/34 | 115 | 34 | 3.5 | 1.0-1.5 |

| 16/5 | 16 | 5 | 2.1 | 1.0-1.5 | 140/42 | 140 | 42 | 3.3 | 1.0-1.5 |

| 22/6 | 22 | 6 | 2.4 | 1.0-1.5 | 160/50 | 160 | 50 | 3.3 | 1.0-1.5 |

| 28/6 | 28 | 6 | 2.7 | 1.0-1.5 | 180/58 | 180 | 58 | 3.3 | 1.0-1.5 |

| 33/8 | 33 | 8 | 2.6 | 1.0-1.5 | 235/65 | 235 | 65 | 3.7 | 1.0-1.5 |

| 40/12 | 40 | 12 | 2.6 | 1.0-1.5 | 300/75 | 300 | 75 | 3.8 | 1.0- 1.2 |

| 55/16 | 55 | 16 | 2.7 | 1.0-1.5 | 350/100 | 350 | 100 | 4.3 | 1.0-1.2 |

| 65/19 | 65 | 19 | 2.9 | 1.0-1.5 | 410/150 | 410 | 150 | 4.3 | 1.0-1.2 |

| 75/22 | 75 | 22 | 3.0 | 1.0-1.5 | |||||

RCS-R2 Medium wall tubing without hot melting adhesive |

|||||||||

| Size

(mm) |

As supplied

(mm) |

After recovered

(mm) |

Standard length | Size

(mm) |

As supplied

(mm) |

After recovered

(mm) |

Standard length | ||

| D*(Min.) | d*(Max.) | w*(Min.) | D*(Min.) | d*(Max.) | w*(Min.) | ||||

| 12/3 | 12 | 3 | 1.8 | 30m/spool

or 1.0-1.5m |

95/25 | 95 | 25 | 3.6 | 15m/spool

or 1.0-1.5m |

| 16/5 | 16 | 5 | 2.1 | 30m/spool

or 1.0-1.5m |

115/34 | 115 | 34 | 3.5 | 15m/spool

or 1.0-1.5m |

| 22/6 | 22 | 6 | 2.4 | 30m/spool

or 1.0-1.5m |

140/42 | 140 | 42 | 3.3 | 1.0-1.5m |

| 28/6 | 28 | 6 | 2.7 | 30m/spool

or 1.0-1.5m |

160/50 | 160 | 50 | 3.3 | 1.0-1.5m |

| 33/8 | 33 | 8 | 2.6 | 30m/spool

or 1.0-1.5m |

180/58 | 180 | 58 | 3.3 | 1.0-1.5m |

| 40/12 | 40 | 12 | 2.6 | 30m/spool

or 1.0-1.5m |

235/65 | 235 | 65 | 3.7 | 1.0-1.5m |

| 55/16 | 55 | 16 | 2.7 | 30m/spool

or 1.0-1.5m |

265/75 | 265 | 75 | 3.7 | 1.0-1.2m |

| 65/19 | 65 | 19 | 2.9 | 30m/spool

or 1.0-1.5m |

350/100 | 350 | 100 | 4.3 | 1.0-1.2m |

| 75/22 | 75 | 22 | 3.0 | 30m/spool

or 1.0-1.5m |

410/150 | 410 | 150 | 4.3 | 1.0-1.2m |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered

w*= Outer Layer Wall thickness after fully recovered