Description

Key Features:

Tracking Resistant:

Prevents electrical tracking, ensuring safety and reliability in critical busbar insulation applications.

UV Resistant:

Withstands prolonged exposure to outdoor environments, making it ideal for installations requiring long-term durability.

Flame Retardant:

Minimizes fire risks, enhancing safety in medium-voltage busbar systems.

Flexible Design:

Adapts easily to irregular shapes and contours for a precise, secure fit in busbar insulation.

Shrink Ratio 2.5:1:

Accommodates a wide range of busbar sizes, improving installation efficiency by covering multiple cable dimensions.

High-Temperature Performance:

Fully recovers at a minimum of 120℃, ensuring a tight and reliable fit.

IEC 60684-3-283 Compliant:

Meets international standards for electrical insulation materials, guaranteeing quality and reliability.

Applications:

Busbar Insulation for Medium-Voltage Systems:

Perfect for medium-voltage busbar insulation in power systems operating up to 36kV.

Power Distribution Networks & Industrial Applications:

Ideal for industrial systems, renewable energy systems, and power distribution that require robust insulation and environmental protection.

Why Choose RCS-BTM/RCS-BTH Heat Shrink Tubing?

The RCS-BTM/RCS-BTH provides superior protection for medium-voltage busbar systems, offering flame retardant and UV-resistant properties, along with tracking resistance for enhanced safety. With a 2.5:1 shrink ratio, it fits a wide range of busbar sizes, making it a versatile choice for industrial and power distribution applications. IEC compliance ensures it meets global standards for electrical insulation, offering peace of mind for all installations.

Shelf Life & Storage:

The RCS-BTM/RCS-BTH heat shrink tubing has a shelf life of over 5 years when stored in a humidity-controlled environment (temperature range -10°C to 40°C, relative humidity <75%).

Ordering Information:

- Standard Colors: Brown and Red (custom colors available upon request)

Typical technical performances:

| Test Items | Test Method | Test Requirements |

| Tensile strength | ASTM D 2671 | 12MPa min. |

| Ultimate elongation | ASTM D 2671 | 400% min. |

| Tensile strength after

Aging at 120℃ for 168hrs |

ASTM D 2671 | 10MPa min. |

| Ultimate elongation after

Aging at 120℃ for 168hrs |

ASTM D 2671 | 300% min. |

| Density | ASTM D 792 | 1.2~1.3g/cm3(nom.) |

| Dielectric strength | IEC 60243 | 12kV/mm(3mm) min. |

| Volume resistivity | IEC 93 | 1012Ω.cm min. |

| Flammability | IEC 60684-2 Method C | 60sec max. |

| Low-temperature flexibility

-40℃/4hrs |

ASTM D 2671 Proc. C | No cracking |

| Permittivity | IEC 60250 | 5 max. |

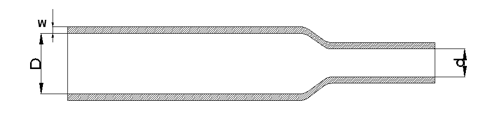

Dimensions:

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length |

Size(mm) |

As supplied(mm) |

After recovered(mm) |

Standard length |

||

D*(Min.) |

d*(Max.) |

w(Min.) |

|||||||

D*(Min.) |

d*(Max.) |

w(Min.) |

|||||||

Medium wall tubing-RCS-BTM |

|||||||||

RCS-BTM15/6 |

15 | 6 | 2.0 | 30m/spool | 100/40 | 100 | 40 | 2.8 | 15m/spool |

RCS-BTM30/12 |

30 | 12 | 2.3 | 30m/spool | 120/50 | 120 | 50 | 2.8 | 15m/spool |

RCS-BTM40/16 |

40 | 16 | 2.5 | 30m/spool | 150/60 | 150 | 60 | 3.3 | 1.0-1.5m |

RCS-BTM50/20 |

50 | 20 | 2.5 | 15m/spool | 205/75 | 205 | 75 | 3.8 | 1.0-1.2m |

RCS-BTM75/30 |

75 | 30 | 2.6 | 15m/spool | 235/75 | 235 | 75 | 3.8 | 1.0-1.2m |

Heavy wall tubing-RCS-BTH |

|||||||||

RCS-BTH25/10 |

25 | 10 | 4.0 | 1.0-1.5m | 120/40 | 120 | 40 | 4.1 | 1.0-1.5m |

RCS-BTH40/16 |

40 | 16 | 4.0 | 1.0-1.5m | 150/60 | 150 | 60 | 3.9 | 1.0-1.5m |

RCS-BTH75/25 |

75 | 25 | 4.0 | 1.0-1.5m | 180/75 | 180 | 75 | 4.1 | 1.0-1.2m |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered